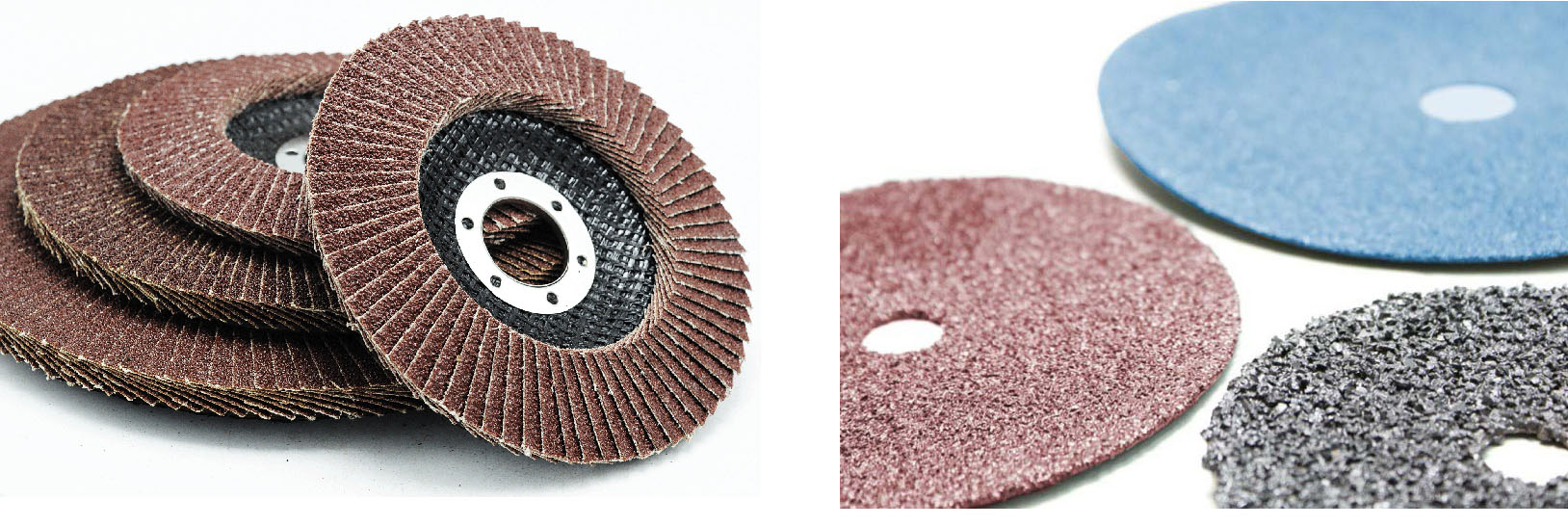

Choosing between Fiber Discs and Flap Discs depends on your task’s needs, material, and finish requirements. Here’s a simplified guide:

1. Material Removal

Fiber Disc:

• Best for fast, aggressive material removal.

• Ideal for heavy-duty tasks like weld removal, deburring, and rust stripping.

• Suitable for hard materials like steel and stainless steel.

Flap Disc:

• Better for controlled and precise material removal.

• Great for finishing, polishing, and surface blending.

• Works well on softer metals like aluminum or non-metal materials.

2. Surface Finish

Fiber Disc:

• Leaves a rougher finish, suitable for preparation steps before further processing.

Flap Disc:

• Leaves a smoother, polished surface, perfect for final finishing tasks.

3. Durability

Fiber Disc:

• Wears out faster but is cheaper upfront.

• Best for short-term, high-intensity tasks.

Flap Disc:

• Lasts longer due to its layered structure.

• Suitable for extended use and lower tool replacement frequency.

4. Comfort and Noise

Fiber Disc:

• Produces more vibration and noise.

Flap Disc:

• Quieter and more comfortable, ideal for long sessions.

5. Cost

• Fiber Disc: Lower initial cost but may need frequent replacement.

• Flap Disc: Higher upfront cost but often more economical in the long run for finishing tasks.

Quick Recommendation:

Use Fiber Disc for:

Heavy grinding, fast material removal, and rough work.

Use Flap Disc for:

Surface finishing, polishing, and tasks requiring precision and comfort.

Choose based on whether speed or surface quality is your priority!